Pipe Fittings

I put the carriage before the horse. Getting compatible fittings, adapters etc. should have come first.

My original plan was to aim for maximum compatibility & originality -- simply recreating the car's original configuration, but with E85-compatible materials. This would mean replacing the body-to-engine feed and return hoses in the engine room with identical parts, getting the flared "screw" fittings fabricated onto the pipe ends, and replacing all O-rings. It turns out this wasn't so simple after all.

Apparently the "flared end + thread" fitting used in the fuel lines is a GM-specific thing, and fabricating it onto a raw piece of pipe requires a special tool.

This fitting is found in

- Fuel feed line,

- between level sender assy and rear body pipe

- between rear body pipe and fuel filter intake

- between fuel filter exit and front body pipe

- between front body pipe and body-to-engine hose

- between body-to-engine hose and engine pipe

- between engine pipe and TBI unit (adapter)

- Fuel return line,

- between TBI unit (adapter) and engine pipe

- between engine pipe and body-to-engine hose

- between body-to-engine hose and body pipe

All other hose-pipe fittings use simple clamps.

I've queried

American Service,

South West Trade,

US Parts,

Metro Auto,

Specialty Engineering and

Hydromarket whether it was possible to fabricate the male end to an existing pipe, or if any kind of adapters to either the male or female side of this attachment are available. No-one seems to even know about such adapters, and the the repair shops don't have the equipment to create the flared pipe ends either.

For the record, a

GM Fuel Line Flaring Tool Kit goes for between $203 and

$360 in the US, so I'm surprised that even reputable shops don't have them.

The TBI Fuel Pipe Fitting

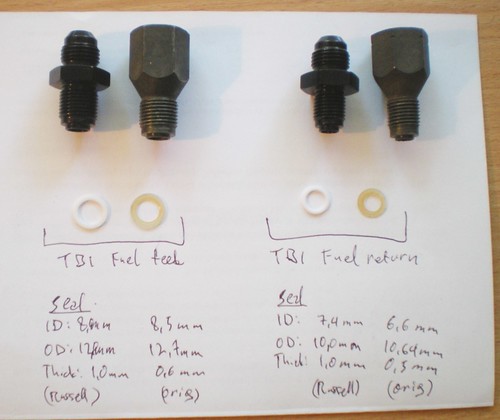

Finally, I noticed that the connectors at the end of the Throttle Body are different. This will at least allow me to attach something to the throttle body. The pipes that run along the engine block do have the GM-specific connectors in both ends, but they attach to the TBI via these adapters:

Left: fuel feed pipe adapter. The male thread is apparently an M14x1.25 (measured diameter 13.7 mm,

thread pitch 1.25 mm)

Right: fuel return pipe adapter. This seems to be an M12x12.5 thread (measured diameter: 11,8 mm, thread pitch 1.25 mm).

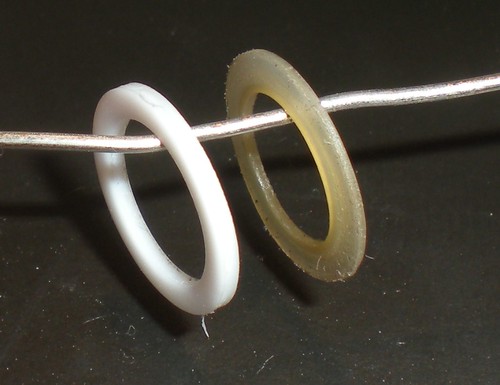

Notice the white plastic(?) ring at the end of each adapter. They probably work as seals, so simply screwing an adapter with the same thread, but without the seal, wouldn't suffice.

The behind of the Throttle Body, w/o the adapters. Fuel feed pipe on the left (exposed), fuel return pipe on the right (covered in duct tape):

It was impossible to get useful measurements of the available space around the ports, so after carefully removing dirt from around the TBI unit, I screwed it off from the intake manifold and took it shopping. It's attached with three bolts, left, right and front.

The TBI unit removed:

The intake manifold exposed. Engine oil was coming out of the TBI bolt hole on the driver's side. In this pic I had also removed the fuel return pipe, and the fuel feed pipe is loose on the right side (details below).

After a few iteration around the shops, a helpful sales rep at US Parts managed to find adapters that fit the female threads in the Throttle Body. The adapters then let you connect

AN system hose fittings and hoses, specifically size AN-6, which means a hose inner diameter of 6 * 1/16" = 3/8" = 9.525 mm. The original fuel feed line was probably 3/8" as well.

The magical pair of adapters in question is one of

Russell 640813 and

640803 (black, anodized) or

640800 and

640810 (blue, nickel plated). The black ones were ordered and should arrive in 1-2 weeks.

Removing the Engine Fuel Pipes (1)

Since I'll be connecting hoses directly to the back of the TBI, the engine fuel feed and return pipes are redundant. Due to their shape and the flared ends, the pipes can't simply be pulled out though. The easiest way to remove them would be to split them in half with a pipe cutter, but I simply can't bring myself to destroying original components that are still in fine usable condition. So, we'll disassemble parts until they come out.

To get the fuel return pipe out, I had to remove

- PCV filter and hose (attach to the driver's side valve cover)

- Brake booster vacuum pipe (front of TBI / intake plenum)

- The 3 throttle cables attached to the side of the TBI (throttle pedal, cruise control and ??)

- Positive cable at the back of the charger

- Upper coolant hose

- Driver's side valve cover

Even then, it's too tight between the charger and the rocker box to get the thicker fuel feed pipe out. There are some nasty scratches on the pipe already.

... more to follow.